Client Overview

Our client was a publicly contracted solar operations firm managing renewable energy systems at municipal facilities. In this case, they oversaw a 1.2 MW ground-mounted solar array installed at a wastewater treatment plant in Northern California. The site supported a city of 100,000+ residents and operated continuously, with a solar array powering 60–70% of the facility’s electrical load. The EPC/O&M team had about 40 personnel and maintained renewable systems at six public works sites across the region.

The Project

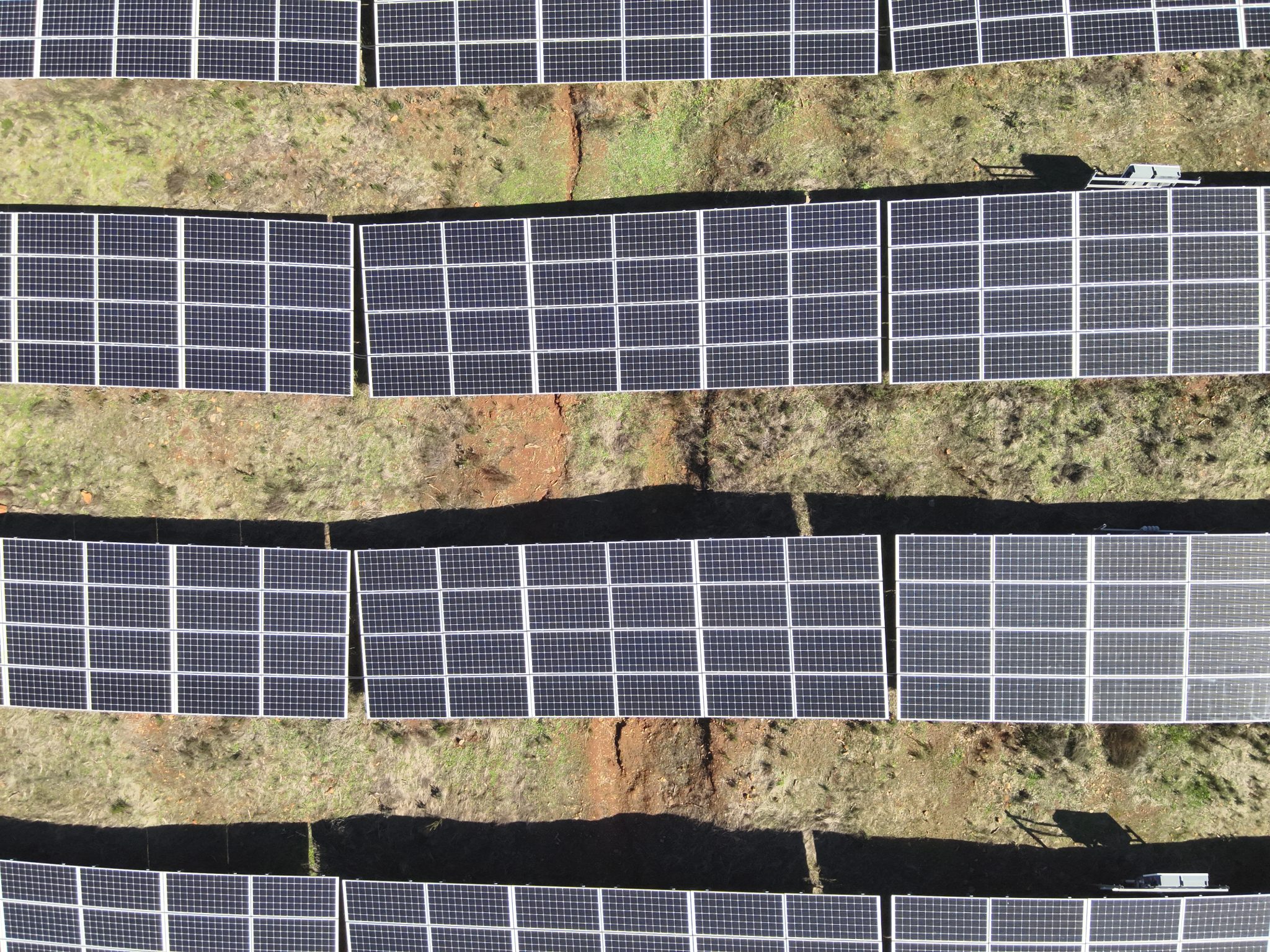

The project involved conducting a high-resolution thermal audit of a 1.2 MW ground-mounted solar array at a wastewater treatment plant in Northern California, managed by a publicly contracted solar operations firm. Prompted by a 14% decline in energy production over two months, the audit aimed to identify malfunctioning modules, strings, or junction boxes, assess potential impacts from wastewater vapors, dust, or environmental buildup, and deliver a precise asset report. Leveraging advanced thermal imaging and data analytics, the project sought to diagnose performance issues, optimize energy output, and restore cost-saving utility offsets for the facility serving over 100,000 residents.

The Problem

The treatment plant had been reporting a gradual but noticeable degradation in solar energy production over a two month span, approximately a 14% performance dip. Given the plant’s high-energy processes (aeration, UV disinfection, and pumping systems), this underperformance was impacting utility offsets and cost savings. Manual inspections had not found any major faults, and the O&M team needed a high-resolution thermal audit to:

- Identify malfunctioning modules, strings, or junction boxes

- Determine if wastewater vapors, dust, or environmental buildup were contributing to thermal stress

- Deliver a precise asset report without interrupting operations or risking ground worker exposure to industrial hazards

Our Solution

We were brought in to gather imagery and data for a radiometric thermal inspection of the solar array using a specialized drone outfitted with a thermal and a high-resolution RGB camera. We developed a site-specific flight plan to:

- Scan 100% of the solar array (over 3,700 modules) within a 2-hour window of solar noon for accurate readings.

- Map hot spots, diode failures, cracked cells, soiling, and string-level disconnections using both thermal and RGB imagery.

- Deliver a detailed orthomosaic with module-level thermal data and mapped GPS coordinates, along with the weather conditions of the day in order to assess the data’s accuracy.

Operational Approach:

- Pre-Flight Coordination:

We reviewed sectional utility layouts and received authorization from the municipal facilities director. Our team conducted a safety survey due to proximity to treatment tanks and digesters, as well as the high voltage of the solar array. We ensured we had sterile launch zones and emergency procedures/protocols in place to help keep worker safety. - Thermal Mission Execution:

Flights were conducted at ~100 ft AGL with a 75° oblique angle for optimal thermal contrast. Overlapping raster flight paths were used to build a detailed orthomosaic, while low-altitude spot flights verified key anomalies. - Post-Processing and Analytics:

We processed over 100 GB of imagery using Pix4D Mapper and FLIR Tools to generate a complete hotspot index. Each issue was tagged with a unique ID, severity score, and module/row reference for maintenance teams.

Risks & Challenges

- Weather & Thermal Noise:

This solar scan was conducted during the winter months, which meant there were limited days for collection and operation. In order to have accurate readings, the sun needed to be out for most of the day, and had to provide an acceptable irradiance level. This also means there could be no cloud coverage or rain the day prior, or that would skew the readings. - Airspace Awareness:

The treatment plant was within 3 miles of a general aviation airport. We coordinated with the tower and submitted a LAANC request to fly under 200 ft AGL in controlled airspace. - Job Site Hazards:

Gathering data from an active solar array means that the team had to acknowledge and understand the risk of high voltage. We deployed a remote takeoff zone and maintained visual line-of-sight at all times. Proper PPE was maintained, as well as coordination with the plant staff in case of emergency. - Panel Reflectivity & Surface Interference:

A combination of wastewater mist, dust, and algae buildup on some panels created false readings. We mitigated this by cross-referencing RGB images and confirming visual obstructions vs. true thermal signatures.

Key Numbers

- Flight Time: 2.6 flight hours

- Modules Scanned: Over 3,700

- Site Area: ~7.5 acres

- Thermal Data Captured: 100+GB

- Anomalies Identified: Over 60 (including 12 critical modules with bypass diode failure and 1 compromised string)

- Flight Altitude: 100 ft AGL, following terrain.

- Operational Window: 11:00AM – 1:00PM (solar noon window)

- Completion Time: 2 days total (including processing and reporting)

- Deliverables: Thermal orthomosaic, PDF inspection report, CSV anomaly index, and GeoTIFF overlays for GIS teams,

Project Results and Impact

The inspection revealed a failing string due to a compromised junction box and a cluster of panels heavily impacted by particulate buildup near an aeration tank. After cleaning and targeted repairs, the facility recovered over 11% of its lost production within 10 days. The client was impressed by the non intrusive approach and contracted us for quarterly preventive scans across multiple municipal solar assets.